Researchers at Northern Illinois University (NIU) and the National Renewable Energy Laboratory (NREL) of the US Department of Energy have just published a report in the journal Nature about a potential breakthrough in developing hybrid solar cells.

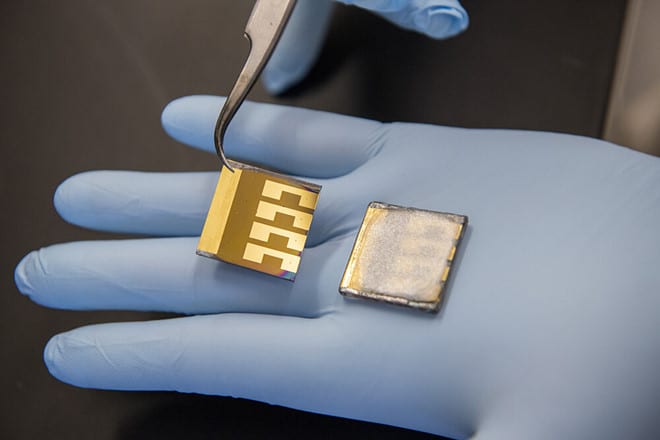

Two samples of solar cells in the laboratory, the right battery has lead absorption film on the back

Like the rising star in the field of solar energy, perovskite has the ability to convert light into electricity. They are simpler to manufacture and cheaper to produce, but offer the same efficiency as traditional silicon solar cells, at least on a small scale in a lab.

However, challenges remain before perovskite solar cells become commercially competitive technology. One of the top challenges is the use of lead. Most high-performance perovskite hybrid solar cells contain water-soluble lead, which raises concerns about the possibility of lead leakage from damaged battery cells.

Led by NIU professor Tao Xu and NREL senior scientist Kai Zhu, a team of scientists developed a new technique to isolate the lead used to make perovskite solar cells and minimize them. Toxic leakage by applying lead absorption membrane to the front and back of the battery.

More specifically, a transparent lead-absorbing membrane is attached to the conductive glass layer on the front of the solar cell. The isolated membrane contains groups of phosphonic acids that strongly bond with lead but do not prevent the cell from storing light to convert it into electricity. Meanwhile, a cheaper polymer film is mixed with lead-forming agents used on metal electrodes on the back.

“The lead toxicity issue is one of the most frustrating last-step challenges in the field of perovskite solar cells. We think we have very promising remedies for this problem and it can be a game-changer. In case the battery cell is damaged, our device will hold most of the lead, preventing it from seeping into groundwater and soil. The membranes we use are insoluble in water, ”said Professor Tao Xu.

For severely damaged battery cells used in laboratories, lead-absorbing films isolated 96% of the lead. Subsequent experiments by the scientists showed that the lead absorption layers did not negatively affect battery performance or stability during long-term operation.

The reason perovskite solar cells have such a name is because it uses a crystal structure layer similar to the structure found in a mineral called perovskite. The most common perovskite structure compound in this solar cell is an inorganic hybrid organic halogen material. Scientists began to study this crystal structure for use in solar cells only about a decade ago. The results show that the efficiency of solar conversion increases rapidly. While traditional silicon solar cells are manufactured using high-temperature processes, perovskite batteries can be made by chemical methods at room temperature.

The newly developed “lead isolation approach on devices” can easily be combined with the existing perovskite solar cell configuration, Professor Tao Xu said.

“It is worth noting that lead isolation can also be applied to other perovskite-based technologies such as sensor applications,” said Kai Zhu, a scientist.